Msg 3 Analysis

Reliability Centered Maintenance Rcm Wbdg Whole Building Design Guide

Msg 3 Analysis Course Brochure And Syllabus Regional Services

Coscap Sa Reliability Monitoring Ppt Video Online Download

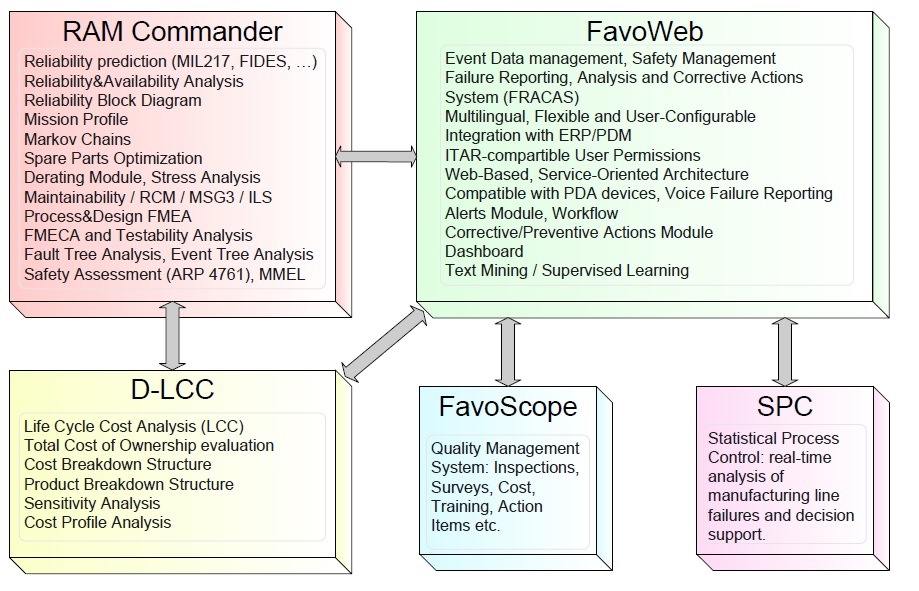

Rams Software Isd Italia

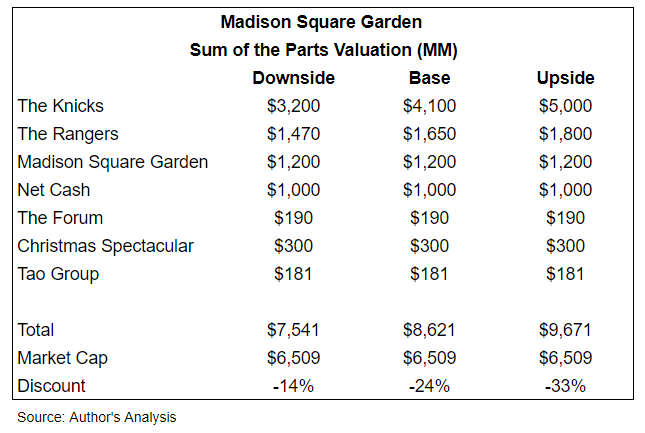

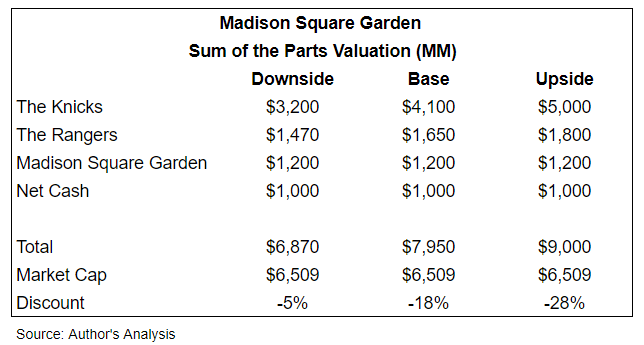

Msg Spin Off What Is The Company Worth Stock Spinoff Investing

2

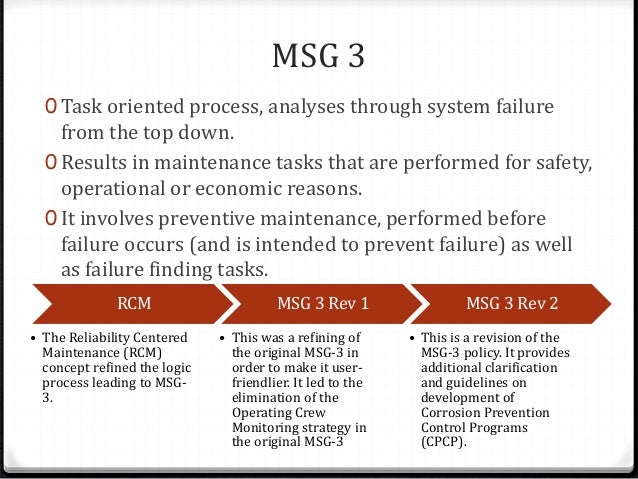

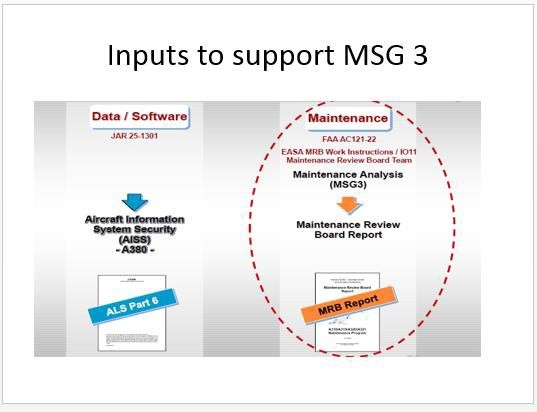

During the MSG-3 Rev.

Msg 3 analysis. MSG-3 Analysis FOR MSI 28-10-00 Fuel Storage System Effectivity:. Over the past two months, BQR’s team performed electrical stress analysis for our company, using fiXtress for two critical projects on a very tight schedule. During the MSG-3 analysis, a team consisting of the OEM, operators and the regulatory authorities analyzed every aircraft system, including airframe structure and wiring installation, to determine the failure modes, their criticality, the ease of their detection, the level of inspection required and the ideal recurrence of inspection.

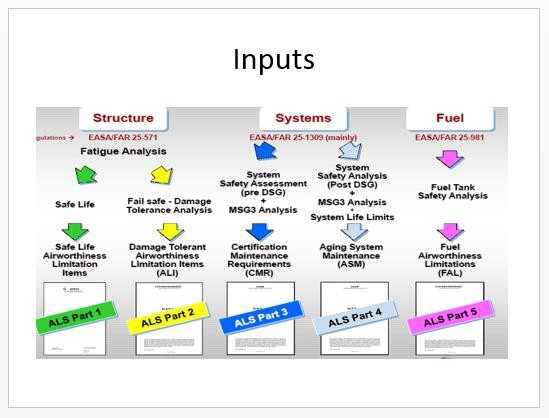

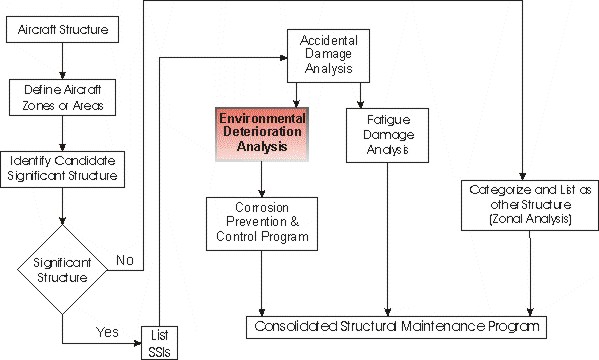

All structural items are identified as either structure significant items (SSIs) or other items. MSG-3 Scheduled Maintenance Development Analysis is divided into 4 main sections:. The MSG-3 Methodology The MSG-3 methodology starts before an aircraft enters into service, at the time that in-service operational data is not available for many systems and components.

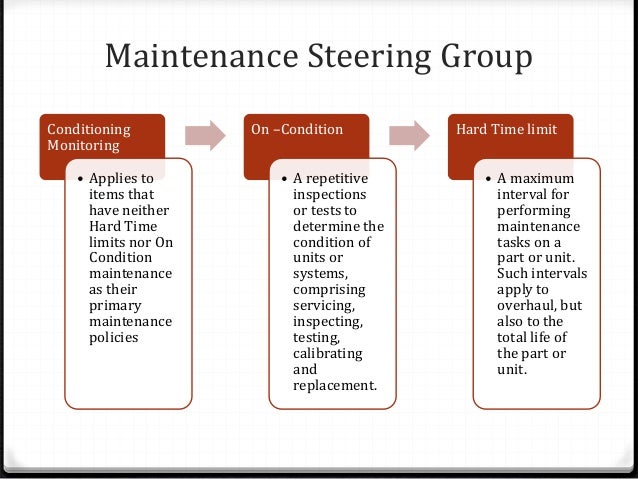

Provide MSG-3 top-notch training. MSG-3 is a Top-down process, which enables a step by step systematic analysis. MSG-3 (Maintenance Steering Group) ‘Operator/Manufacturer Scheduled Maintenance Development’ is a document developed by the Airlines For America (A) (formerly the Air Transport Association or ATA).

I would like to thank BQR for the hard work and the professional reports, especially since the schedules were almost impossible to keep. The process is maintained by A (Airlines For America formerly known as ATA). Project Consultant F-15 MSG-3 Analysis Intergraph Government Solutions September 14 – Present 5 years 2 months.

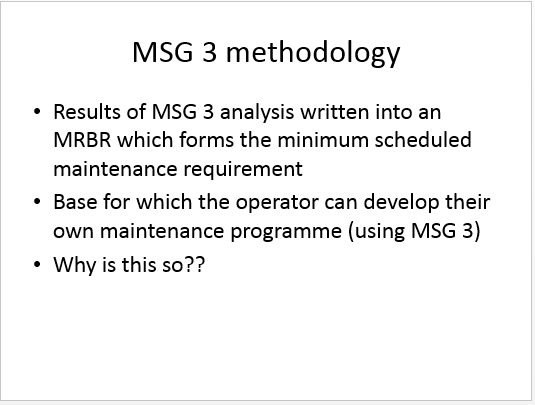

The result of the MSG-3 analysis is published in the MRB (Maintenance Review Board) report. MSG-3 is a structured process for identifying Safety Significant Items (SSI), defining for each SSI the failure modes and effects (FMEA). The remaining maintenance, that is, non-scheduled or non-routine maintenance, consists of maintenance actions to correct discrepancies noted during scheduled maintenance tasks, other non-scheduled maintenance, normal operation, or data analysis.

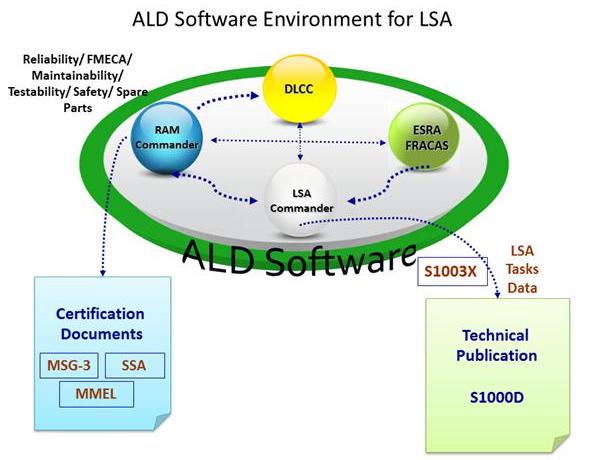

Xwing Fighter Spaceship Revision:. MSG-3 analysis, and maintenance program inspection:. Comprehensive software tool for Reliability and Maintainability Prediction, Reliability Analysis, Spares Optimization, FMEA/FMECA, Testability, Fault Tree Analysis, MSG-3, Event Tree Analysis and Safety (SAE ARP 4761, MIL-STD-8E).

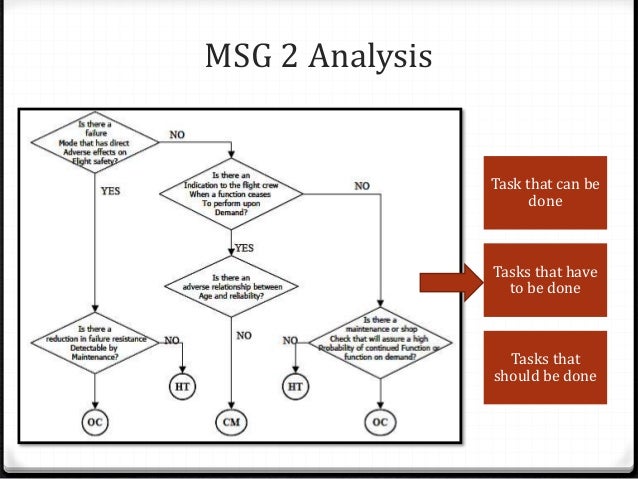

MSG-3 defines what SSIs contribute significantly to carrying flight, ground, pressure or control loads, and which component. How to define the task type abbreviations that are used in tasks. If the analyst answers Yes to at least one of the questions, then detailed analysis is indicated for the equipment.

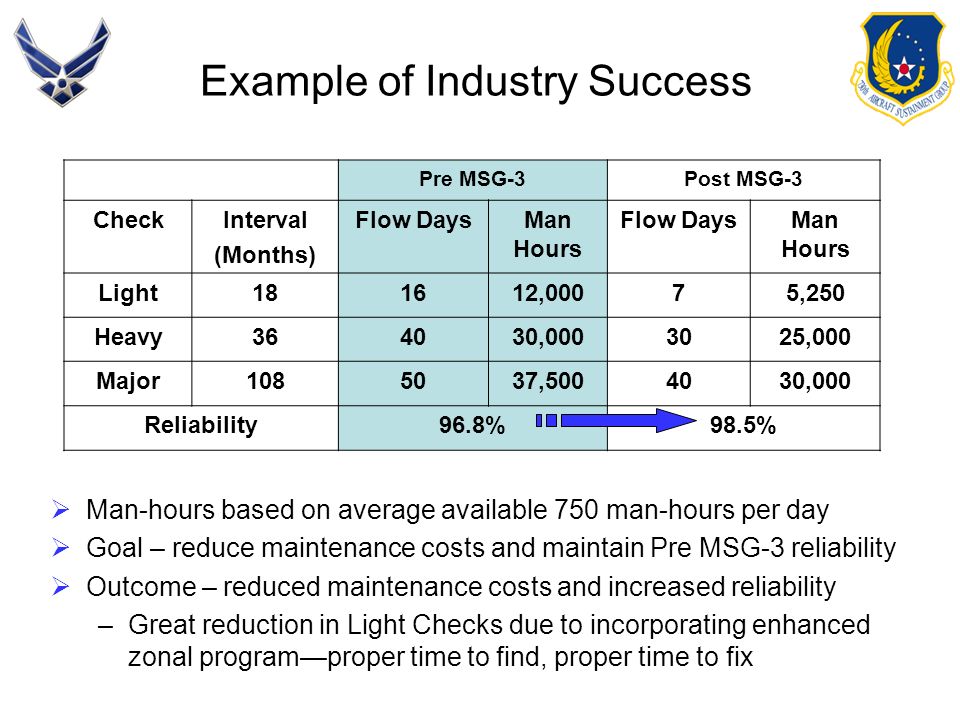

Maintenance Steering Group-3 (MSG-3) is a method for developing preventive maintenance programs in the aerospace industry. Revisions to the MSG-3 philosophy have provided added methodology for improving coverage of all modes of failure, such as inclusion of the Corrosion Prevention and Control Program, Enhanced Zonal Analysis, and Lightning/High Intensity Radiated Fields. The course is designed to meet the needs of aviation personnel who require a comprehensive understanding of MSG.

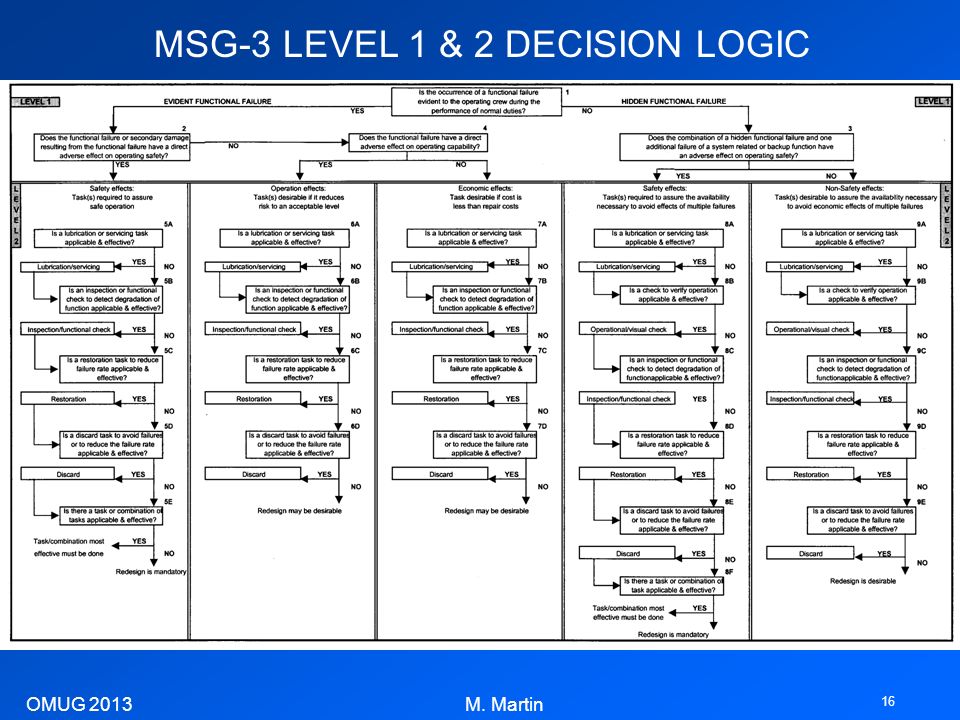

The MSG-3 systems analysis is a robust procedure based on scientific logic and engineering judgment and it has evolved over the last 30 years by constantly making incremental changes based on industry experiences. MSG-3 adjusted the decision logic flow paths to provide a more rational procedure for task definition and a mor e straightforward and linear progression through the decision logic. MSG/3-REPORT 2-1 MSG/3 Report on Agenda Item 2 REPORT ON AGENDA ITEM 2:.

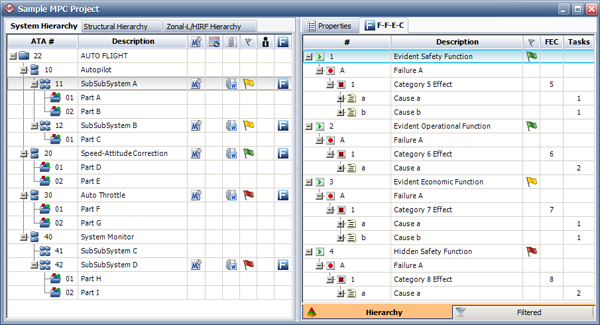

ReliaSoft's MPC software is an MSG-3 compliant maintenance program creator for the aircraft / aerospace industry. Items within the Structural ATA Chapters (51-57) that lend themselves to System analysis (e.g., flight control hinge bearings, fuselage drains, door hinge and mechanisms, etc.) and SHM systems should be. ATA MSG-3 SHM WG Detailed Proposal - Rev 1, dated 01/10/09 2-3-1.

The Origins of MSG-3 Aircraft Maintenance Program - Developments General Introduction to MSG-3 Process Features and Benefits of MSG-3 MSG-3 Analysis Methodology System and Power Plant Analysis Structural Analysis Zonal Analysis EWIS/HIRF. MSG-3 analysis should be applied to the complete certified aircraft, including the engines and propellers. Reliability-centered maintenance (RCM) is a concept of maintenance planning to ensure that systems continue to do what their user require in their present operating context.

RAM Commander integrated MMEL module supports Master Minimum Equipment List generation using Reliability, FMECA, FHA (Safety) and FTA modules results. Successful implementation of RCM will lead to increase in cost effectiveness, reliability, machine uptime, and a greater understanding of the level of risk that the organization is managing. Implementation of the recommendations generated through MSG-3 analysis is the major role of an airline operator in developing an initial maintenance program.

Learn about Structurally Significant Items (SSI), Zonal Maintenance and Lightning/High Intensity Radiated Field (L/HIRF) Analysis. SUPPORT and CONDUCT MSG-3 analysis to achieve optimal balance on aircraft’s maintenance/failures costs and availability & safety improvements. Contains the initial scheduled maintenance program c.

Therefore, many persons with a widely experience are required to determine the best initial maintenance schedule. To successfully perform MSG-3 analysis in RAM Commander, you must be familiar with Basic, Reliability, Maintainability and FMECA (including Functional Blocks issue) modules of RAM Commander. This chapter discusses several common features that are similar in all MSG-3 analyses and/or must be determined up-front by an authorized user.

MSG-3 - What does MSG-3 stand for?. 2 analysis of the 747 Classic and 747-400 MRBRs, the ISCs identified and eliminated redundant maintenance tasks in the areas of systems and power plant maintenance and structures main- tenance. Aeronovo specializes in MSG 3 Analysis.

Leads team of highly skilled analyst to rebase line the F-15. For each component, the analysts review the available technical data, such as reliability and maintainability characteristics and description and operation documentation. The 747 Classic ISC also added a zonal maintenance program for the 747 Classic that complies with MSG-3 Rev.

MSG-3 is a voluntary structured process developed by the industry and maintained by ATA (A) to make decisions that are used to develop scheduled maintenance and inspection tasks and intervals for aircraft that will be acceptable to the regulatory authorities, the operators, and the manufacturers. Carriers as the OAMP (On Aircraft Maintenance Planning) document b. The major difference between MSG-3 and its predecessors is in its holistic.

Potential damage is considered possible from accident, environment or fatigue. Standard for Jet Fuel Quality Control at Airports:. MSI Selection … 1.

Run RAM Commander 2. RAM Commander MSG-3 module is used by aircraft manufacturers or aircraft operators (airlines) to perform aircraft Scheduled Maintenance Development analysis according to Air Transport Association (ATA) Maintenance Steering Group 3 (MSG-3) document. Examine the foundations of reliability and failure characteristics theory – critical in understanding the logic, components and methodology of MSG-3.

The first step in MSG-3 systems and powerplant analysis is to define the systems, subsystems, subsubsystems and parts that make up the aircraft. MSG-3 Course is a two-day training and provides the participant with an initially under-standing of the MSG-3 analysis methodology to ensure up-to-date engineering logic also MSG-3-based maintenance effectively delivers significant improvement of aircraft reliability and operational safety nets while optimizing costs of ownership. • Systems and Power Plant Analysis • Structural Analysis • Zonal Analysis • L/HIRF Analysis (Lightning and High Intensity Radiated Field Analysis) RAM Commander supports all 4 analysis methods.

MSG-3 Maintenance Steering Group;. For more details on course agenda, please click here. Initiating MSG-3 Module 1.

Systems and powerplant analysis. The Bell 525 Relentless has some very robust design requirements for maintainability. MSG-3 logic took a "from the top down" or consequence of failure approach.

Generated new decision logic and analysis procedures contained in a new document called MSG-3. MSG-3 was first published in 1980 is a task orientated and the main idea behind this concept is to recognize the inherent reliability of aircraft systems and components, avoid unnecessary maintenance tasks and achieve increased efficiency. The MSG-3 analysis begins with the development of a complete breakdown of the aircraft systems, down to the component level.

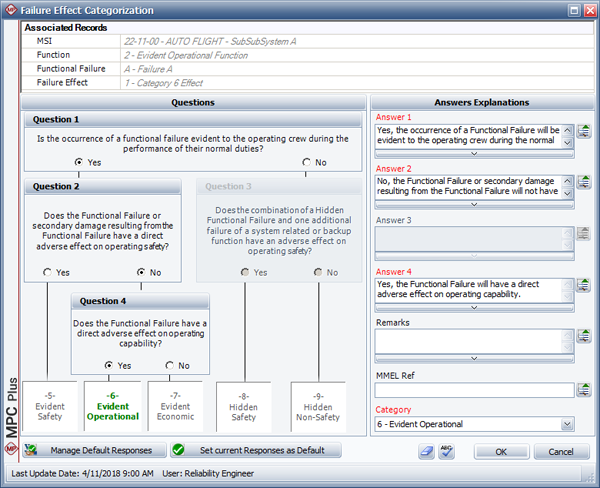

For example, there are four questions in the MSG-3 guideline used to develop initial scheduled maintenance plans for the aircraft industry. MMEL analysis is required for all aircraft manufacturers to certify aircraft safety in different aviation authorities such as FAA, EASA etc. MSG-3 delivers lower maintenance costs with typical savings ranging from 15% to 25% for the same aircraft type on.

Click on "MSG-3" section in the button bar on the left side of the product tree window. Identify maintenance significant items (MSIs) In MPC's System Hierarchy interface, the intuitive tree structure makes it easy to define and manage the system configurations you wish to analyze. The MSG-3 process and guidance is clear that the process applies to the entire aircraft, which would include the engine, APU, and/or propeller, as applicable.

The software has been designed to assist MPC-3 working groups to accurately and efficiently complete risk and maintenance planning analysis in accordance with the guidelines of the " MGS-3:. Guidelines for Aircraft Maintenance Training. The MSG-3 analysis covers aircraft systems, structures, zonal inspections, enhanced zonal inspections, and L/HIRF.

The course is beneficial for persons requiring a comprehensive understanding of MSG-3. RAM Commander MSG-3 module is used by aircraft manufacturers or aircraft operators (airlines) to perform aircraft Scheduled Maintenance Development analysis according to Air Transport Association (ATA) Maintenance Steering Group 3 (MSG-3) document. For each potential failure cause, the MSG-3 guidelines provide task oriented logic to determine the appropriate scheduled maintenance tasks.

B & C PAGE. Operator/Manufacturer Scheduled Maintenance Development, VOLUME 2 - ROTORCRAFT:. A scheduled maintenance program consisting of a set of tasks each of which is generated through RCM/MSG-3 analysis.

The verification of safety-related requirements derived from the PSSA process is as follows (Table 8.3):. The MSG 3 process applies a function, failure, failure effects and causes analysis on each element using a Failure Modes Effect Analysis (FMEA). MSG 3 delivers a top down approach which focuses on the need to ensure either economic viability or to maintain the aircraft system, component or structure in an airworthy condition.

Operator/Manufacturer Scheduled Maintenance Development, VOLUME 1 - FIXED WING AIRCRAFT:. The accuracy and clarity of the MSG-3 process provides a smooth transition for the airline to determine its manpower, parts, tooling, ground equipment, and other related requirements. MSG-3 analysis, and maintenance program inspection.

It aims to present a methodology to be used for developing scheduled maintenance tasks and intervals, which will be acceptable to the regulatory authorities, the operators and the manufacturers. MSG-3 is listed in the World's largest and most authoritative dictionary database of abbreviations and acronyms. MSG-3 is intended to facilitate the development of initial scheduled maintenance programs.

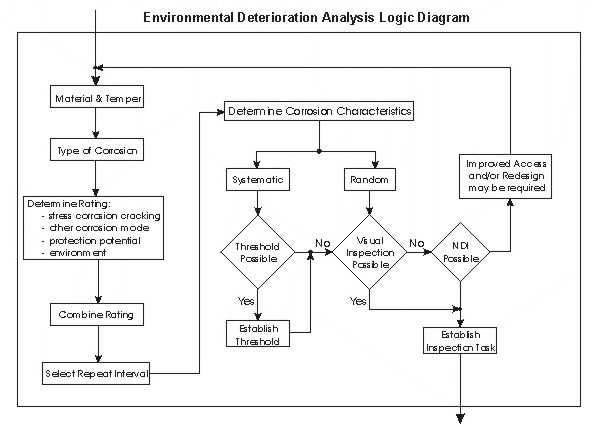

Is known by all U.S. FOLLOW-UP ON THE OUTCOME OF MIDANPIRG/13 MEETING 2.1 The meeting was apprised of the outcome of the Thirteenth meeting of the Middle East Air Navigation Planning and Implementation Regional Group (MIDANPIRG/13) held in Abu Dhabi, UAE, 22 - 26 April 12. The “MSG-3 Structural Maintenance Program Development Logic” is provided to show how each of the deterioration sources (fatigue, environmental, and accidental damage) are assessed separately to provide a structural inspection program for the timely detection of any distress.

Experts for over years for high ranked aviation companies. To conduct the failure analysis and to determine the inspection task packaging for the MSG-3 approach. From the identification of maintenance significant items (MSIs) to the generation of the final report document, MPC guides you through the entire MSG-3 process for aircraft systems and powerplant analysis:.

Q Tbn 3aand9gcsvve4kem Kn3pw0bp0ruwurh4eymxpsqprjenanqijobhemwm9 Usqp Cau

Msg 3 Maintenance Steering Group

Www Easa Europa Eu Download Imrbpb Ip171 r0 scope of fd analysis in msg 3 Pdf

Aircraft Maintenance Program

Maintenance Steering Group Fatigue Concepts

Static Ptbl Co Static Attachments 2177 Pdf

Www Jstor Org Stable

5g Waveform Candidate 5g Sharetechnote

Functional Reliability Centered Maintenance Rcm Module Pennant Ips

Aircraft Maintenance Program

Www Easa Europa Eu Download Imrbpb Ip92and103combined final version Pdf

Aerostat Aviation Courses Msg 3 Analysis Aviation E Learning

Reliability Availability Maintainability And Safety Analysis Software Sohar Service

Msg Treorbis Optimization Through Transparency

On Aircraft Scheduled Maintenance Program Development Emerald Insight

Maintenance Steering Group Fatigue Concepts

Rcm Sample

Techniquant The Madison Square Garden Company Class A Msg Technical Analysis Report For 31 Jul

Aircraft Maintenance Program

International Standard

Msg 3 Systems Analysis Msg 3 Systems Analysis Aircraft Msg Decision Logic Aircraft Maintenance Schedule Changes Analysis System Commercial Aviation

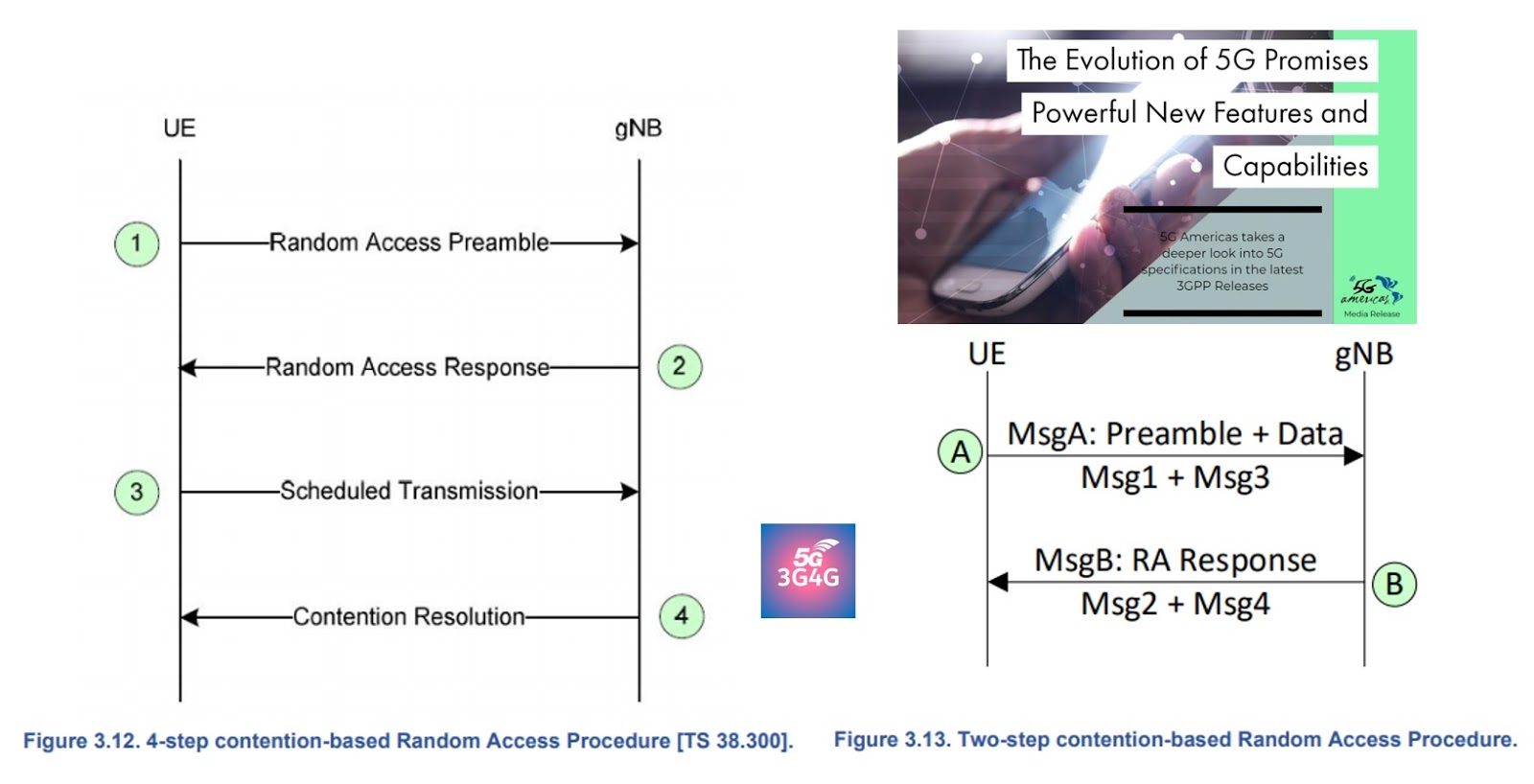

The 3g4g Blog 2 Step Rach Enhancement For 5g New Radio Nr

Ulrica Pen In Aviation Aircraft Maintenance What Is Msg

Msg 3 Maintenance Steering Group

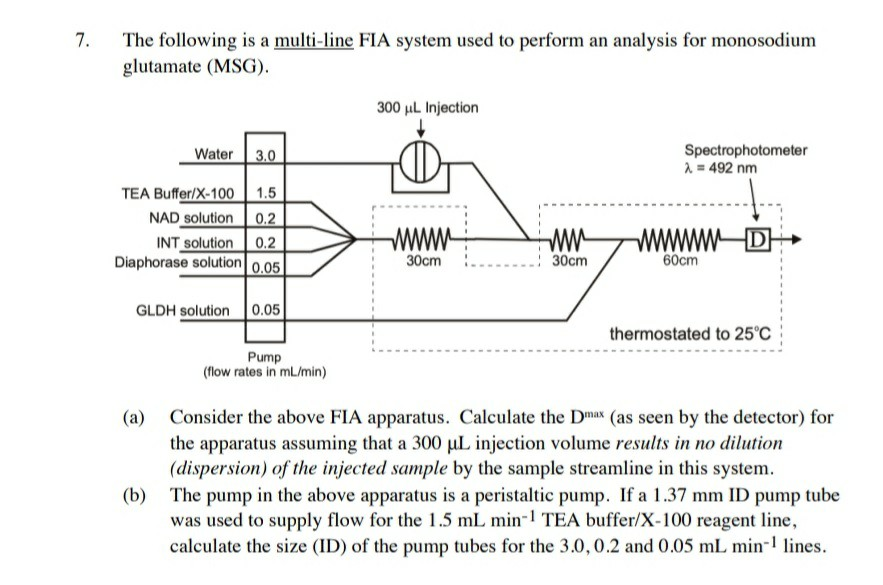

7 The Following Is A Multi Line Fia System Used T Chegg Com

Creating Initial Scheduled Maintenance Plans For Aircraft Msg 3 Reliasoft

Pdf Comparative Analysis On The Effect Of Ems And Msg On The Stomata Of Tinospora Cordifolia Willd Semantic Scholar

Reliability Centered Maintenance And Msg3 Dmd Solutions

Msg Networks Inc Technical Analysis Chart Msgn Marketscreener

2

Www ig At Wp Content Uploads S7 Paul Haslam S Series Spec Day 13 S4000m Pdf

Aircraft Maintenance An Overview Sciencedirect Topics

Aula 14 Analise Msg 3 Zonal Electrical Wiring Aircraft

Msg Spin Off What Is The Company Worth Stock Spinoff Investing

Plos One Age Related Differences In Bitter Taste And Efficacy Of Bitter Blockers

The Catalyst For Msg S Potential Breakout Macro Ops

Aircraft Preventive Maintenance Data Evaluation Applied In Integrated Product Development Process

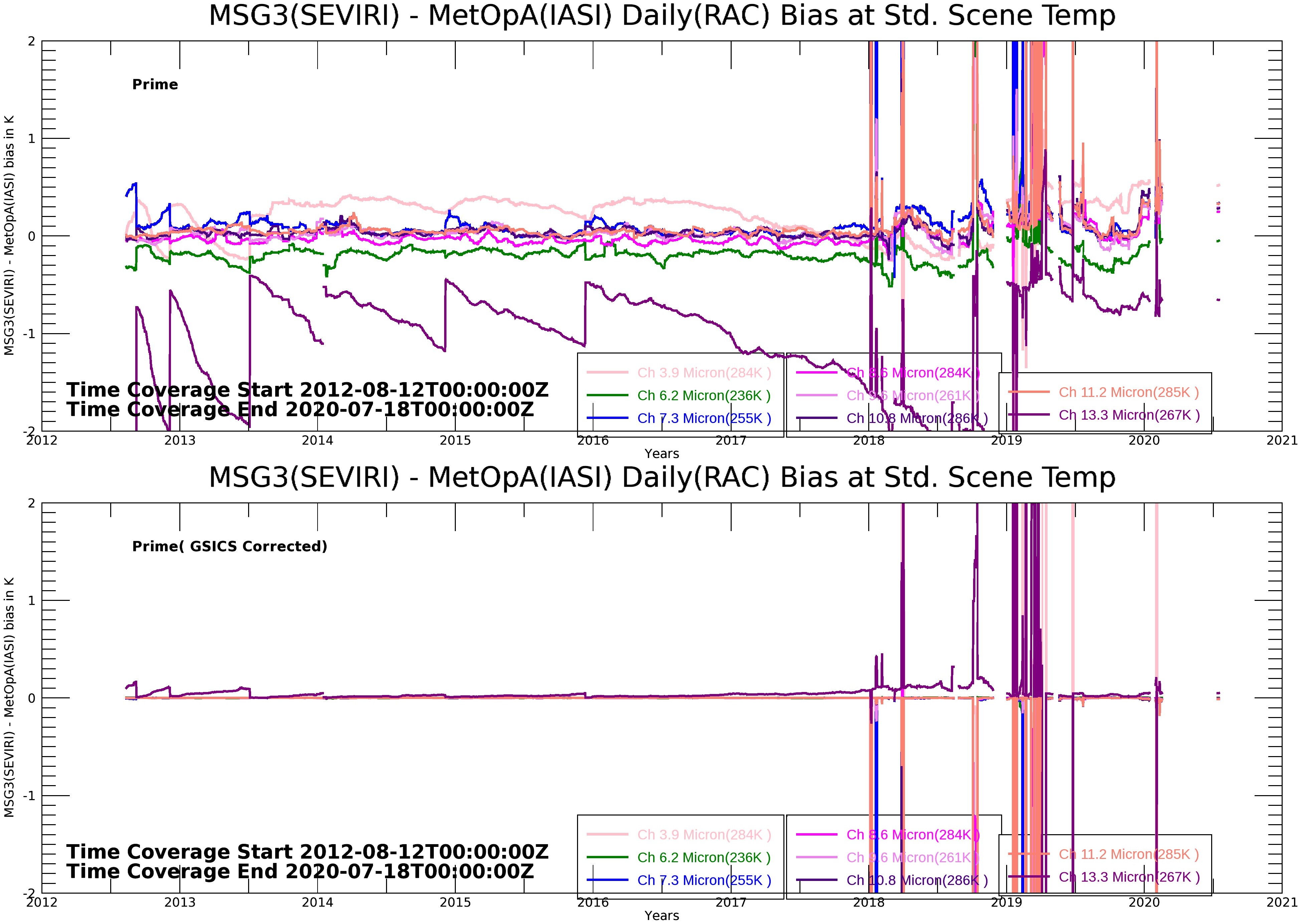

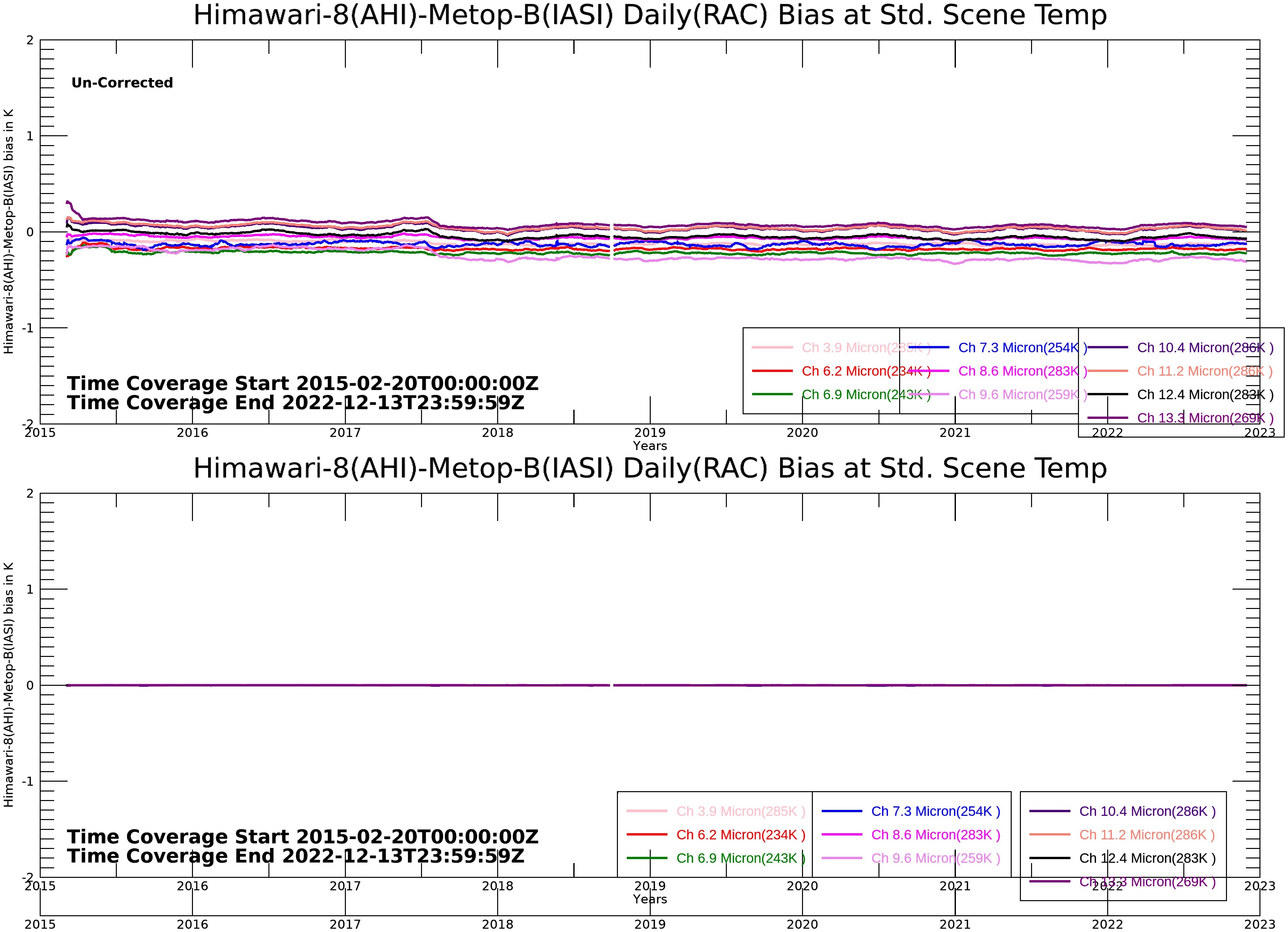

Gsics Coordination Center Product Data

Ppt Maintenance Steering Group 3 Msg 3 Powerpoint Presentation Free Download Id 3244

Creating Initial Scheduled Maintenance Plans For Aircraft Msg 3 Reliasoft

Get Perfect Solution For Msg File Analysis With Multiple Preview Modes Data Forensics Simplified Software Tools For Digital Forensic Analysis

Msg 3

Basic Steps Of Applying Reliability Centered Maintenance Rcm Part Ii

Pdf Glutamic Acid And Monosodium Glutamate Msg Market By Jueekate Issuu

Reliability Centered Maintenance Rcm Wbdg Whole Building Design Guide

Rcm Reliability Expert Center

Logistics Support Analysis Isd Italia

Q Tbn 3aand9gcqijwwefvlep7fdxq6jmgy3e5oyia7qs5yrkxgd96umxj8hr1lr Usqp Cau

2

Basics Of Aircraft Maintenance Programs For Financiers Pdf Free Download

Flow Cytometric Analysis Of Msg Regulation Of l 2 And Bax Levels Download Scientific Diagram

2

Maintenance Steering Group Fatigue Concepts

Maintenance Steering Group 3 Msg 3 Ppt Video Online Download

Http Www Sx000i Org Docs 15uf Ils C 1030 ils day 15 S3000l 14 09 15 Pdf

Reliability Centered Maintenance And Msg3 Dmd Solutions

Maintenance Steering Group Structural Analysis Logic

Lgm North America Tools In Ils Lsa Iss Msg3 Ietm Safety And Lms

Maintainability Analysis Robin Rams Software Suite

Uptime At Minimum Cost In The Process Industries

Maintainability Analysis Robin Rams Software Suite

Www Icao Int Mid Documents 19 Acao Icao airworthiness Session 6 part 21 maimtenance program final Pdf

Maintenance Steering Group Environmental Deterioration Analysis Eda Flow Chart

Aircraft Preventive Maintenance Data Evaluation Applied In Integrated Product Development Process

Implementation Of Msg 3 For Crack Growth Analysis Of Aircraft Ssi Components

Http Www Sx000i Org Docs 15uf Ils C 1030 ils day 15 S3000l 14 09 15 Pdf

Aircraft Maintenance Program

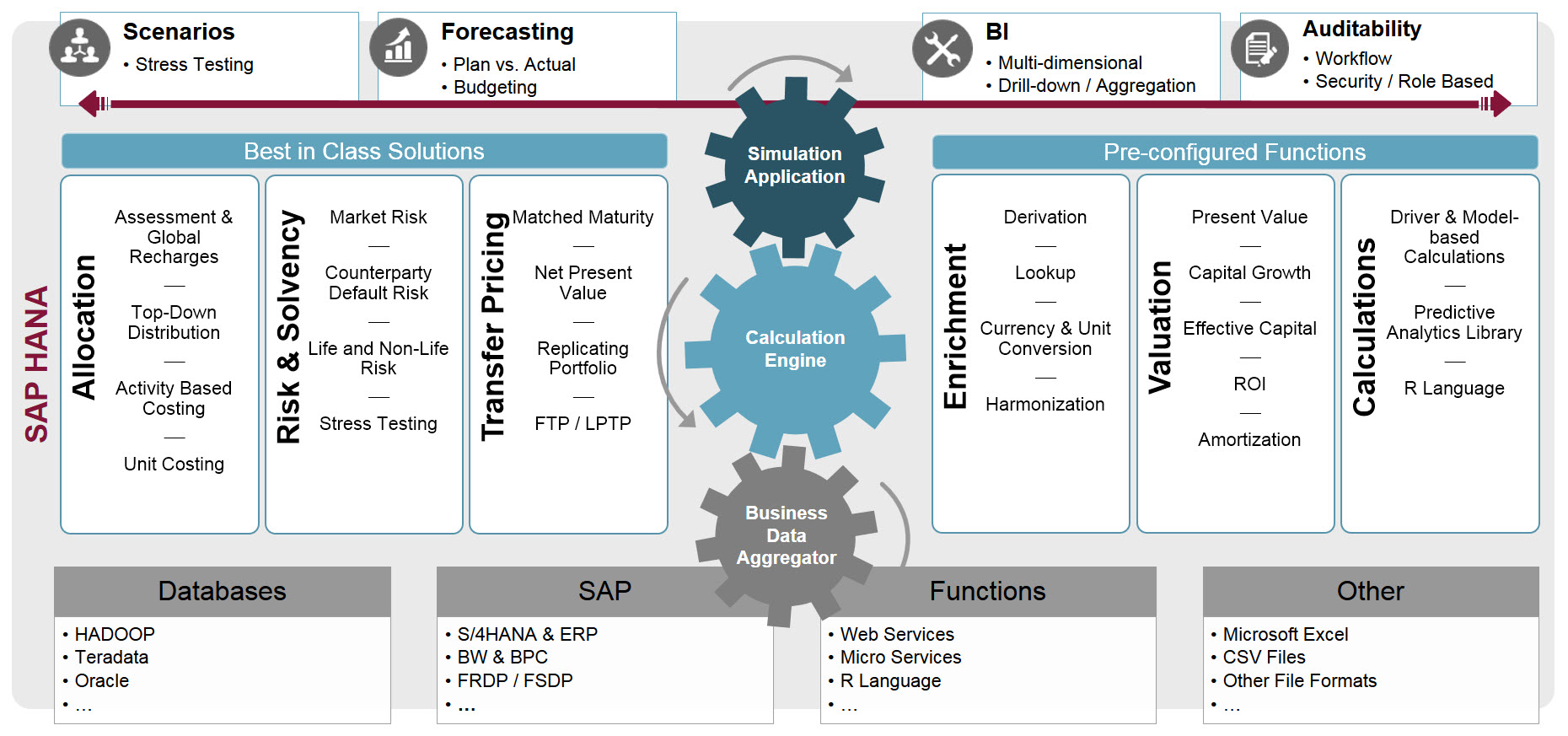

Sap Profitability And Performance Management

Nf 5224 Msg 3 Logic Diagram Download Diagram

Catenae Innovation Plc Technical Analysis Chart Msg Gb Marketscreener

Benefits Of Optimizing Maintenance Intervals Pdf Free Download

Gsics Coordination Center Product Data

5g Waveform Candidate 5g Sharetechnote

Static Ptbl Co Static Attachments 2177 Pdf

Reliability Centred Maintenance Rcm Ppt Video Online Download

Http Www Aldsoftware Com Download Ramc Samplereports Ald Msg3 Report Pdf

Msg 3 Maintenance Steering Group

Basic Steps Of Applying Reliability Centered Maintenance Rcm Part Iii

Msg 3

Hn 8628 Msg 3 Logic Diagram Free Diagram

Creating Initial Scheduled Maintenance Plans For Aircraft Msg 3 Reliasoft

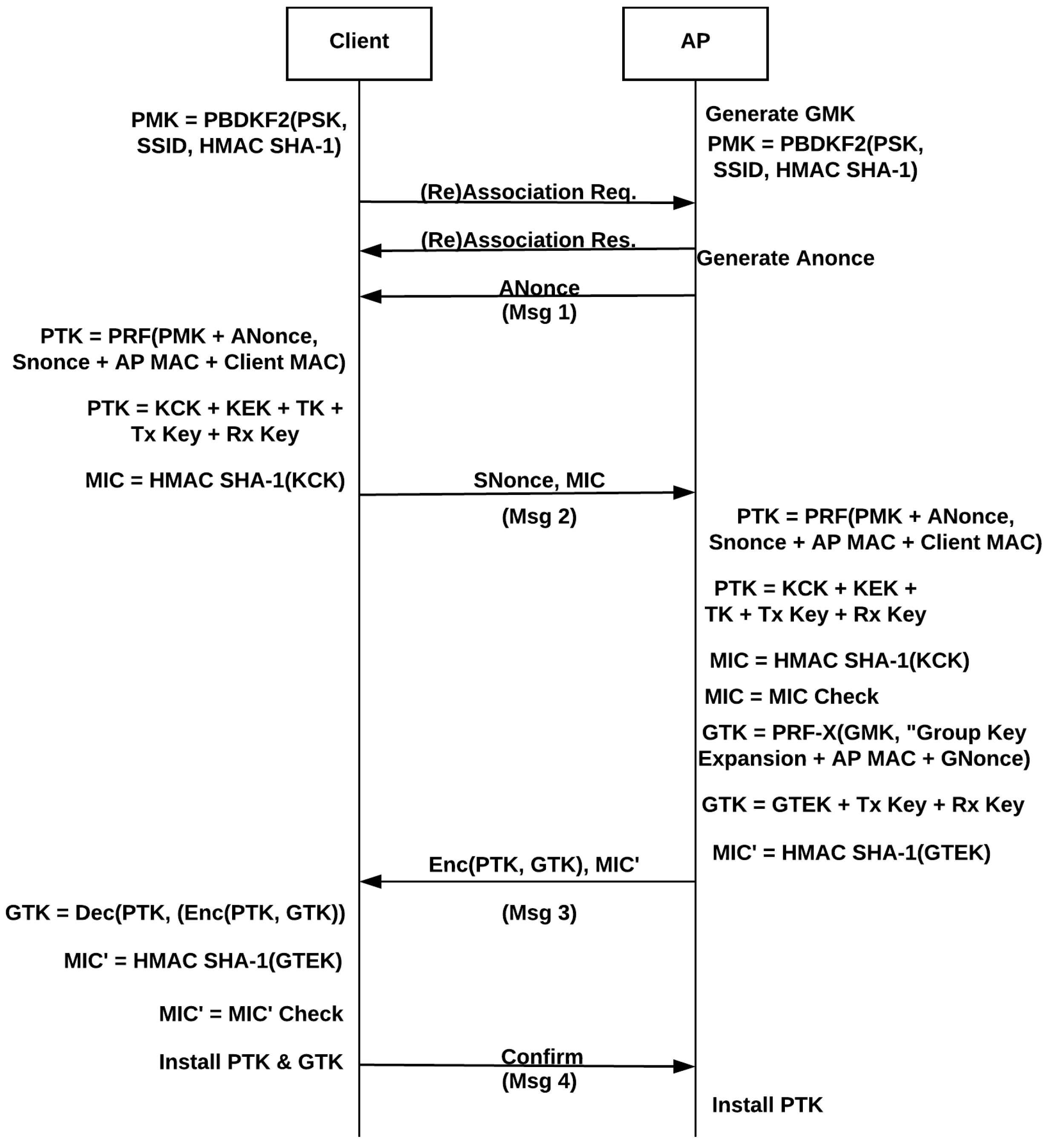

Electronics Free Full Text A Comprehensive Attack Flow Model And Security Analysis For Wi Fi And Wpa3 Html

Www Easa Europa Eu Download Imrbpb Ip 180 ahm integration in msg 3 Pdf

Www Easa Europa Eu Download Imrbpb Ip171 r0 scope of fd analysis in msg 3 Pdf

Aircraft Power Systems An Overview Sciencedirect Topics

Http Www Insight Aviation Com Wp Content Uploads 14 01 Training Leaflet Msg 3 Pdf

Aircraft Preventive Maintenance Data Evaluation Applied In Integrated Product Development Process

2

Http Sassofia Com Wp Content Uploads 15 04 Car M Understanding Msg 3 Methodology And Analytic Process Essentials 1day Dubai Uae Pdf

Www Icao Int Mid Documents 19 Acao Icao airworthiness Session 6 part 21 maimtenance program final Pdf

Msg 3

Diagrams Of The Structure Of P Jirovecii Msg Genes And Msg Proteins Download Scientific Diagram

Ram Commander User Manual

Www Iata Org Contentassets Fafa409c8daebc8451 1115 Oliver Weiss Iata Pao Conference Airbus Ahm Presentation V2 Pdf

Windchill Msg 3 Relex Italia S R L

Www Faa Gov Documentlibrary Media Advisory Circular Ac 121 22c Pdf